The circular economy is becoming a key concept in today’s world, which is facing increasing problems in the field of environmental sustainability and efficient management of natural resources.

CIRCULAR ECONOMY

In essence, the circular economy seeks to change the traditional linear model of “make, use, throw away” to a more sustainable model in which materials and products are designed with their ability to be reused, repaired, recycled or otherwise reused. The main goal of this approach is to minimize the environmental impact that arises as a result of over-exploitation of natural resources and waste generation.

One of the key principles of the circular economy is to shift the focus from one-time use to longer-term use of products. This also includes supporting the design of products to be durable, easily repairable and recyclable. This approach creates a longer life for the products, reducing the amount of waste generated by their disposal.

In practice, the circular economy can mean several different measures and changes in different sectors of the economy. Manufacturing processes can be modified to minimize waste and increase recycling opportunities. Businesses can explore opportunities to share and reuse products, reducing the need to manufacture new ones. Many experts emphasize the advantages of the circular economy, not only in terms of environmental sustainability, but also economic efficiency.

The circular economy does not only mean the saving of natural resources, but also the creation of new jobs and innovation within the economy. Countries and businesses that actively implement a circular economy can become leaders in environmental sustainability while gaining a competitive advantage in a globalized world.

The circular economy can be talked about not only as a theoretical concept, but also as a practical solution to current problems associated with environmental sustainability and efficient use of resources. The challenge is for individuals, businesses and governments to engage in the implementation of the circular economy and support innovation that will lead to a more sustainable and efficient economy for future generations.

The circular economy represents a revolutionary approach to production and consumption, which tries to minimize the negative impact on the environment and use natural resources more efficiently. In an effort to fulfill these goals, an innovative project called CIRCOTRONIC was created in Central Europe.

CIRCOTRONIC is an ambitious project with clear goals. Its main purpose is to support sustainable growth in the field of electrical equipment manufacturing in Central Europe through the transformation towards circular processes. The project focuses not only on the production process itself, but also on the circulation of values, products and services, while we emphasize the efficient use of resources.

You can read more about the CIRCOTRONIC project here.

EXAMPLES OF GOOD PRACTICE

Currently, many companies are undergoing a transformation to a circular economy, and some of them have already successfully integrated elements of this model directly into their production processes. Two prominent examples are the companies EATON and BEKO, which occupy a significant position in their industries thanks to innovation and an active approach to sustainability.

EATON

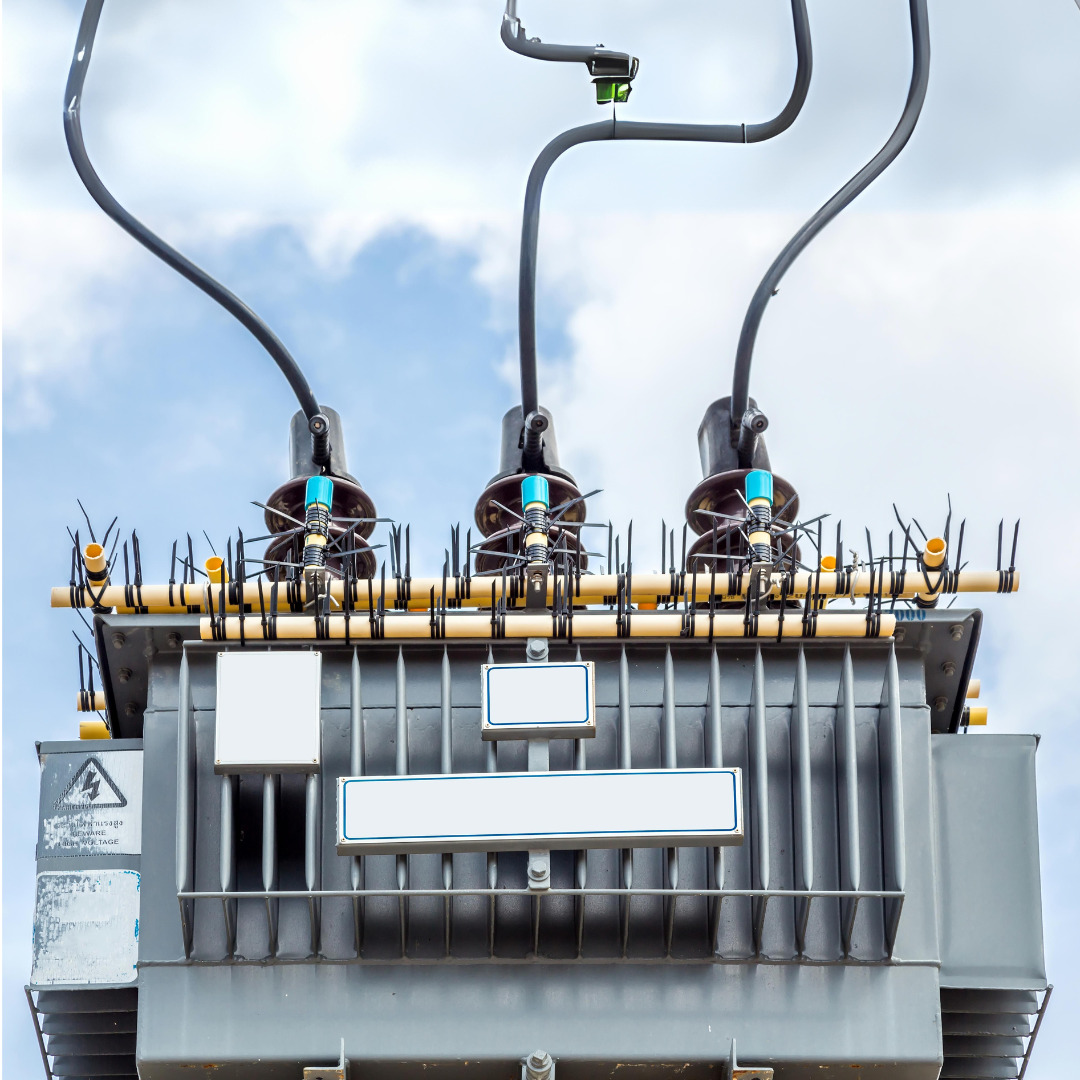

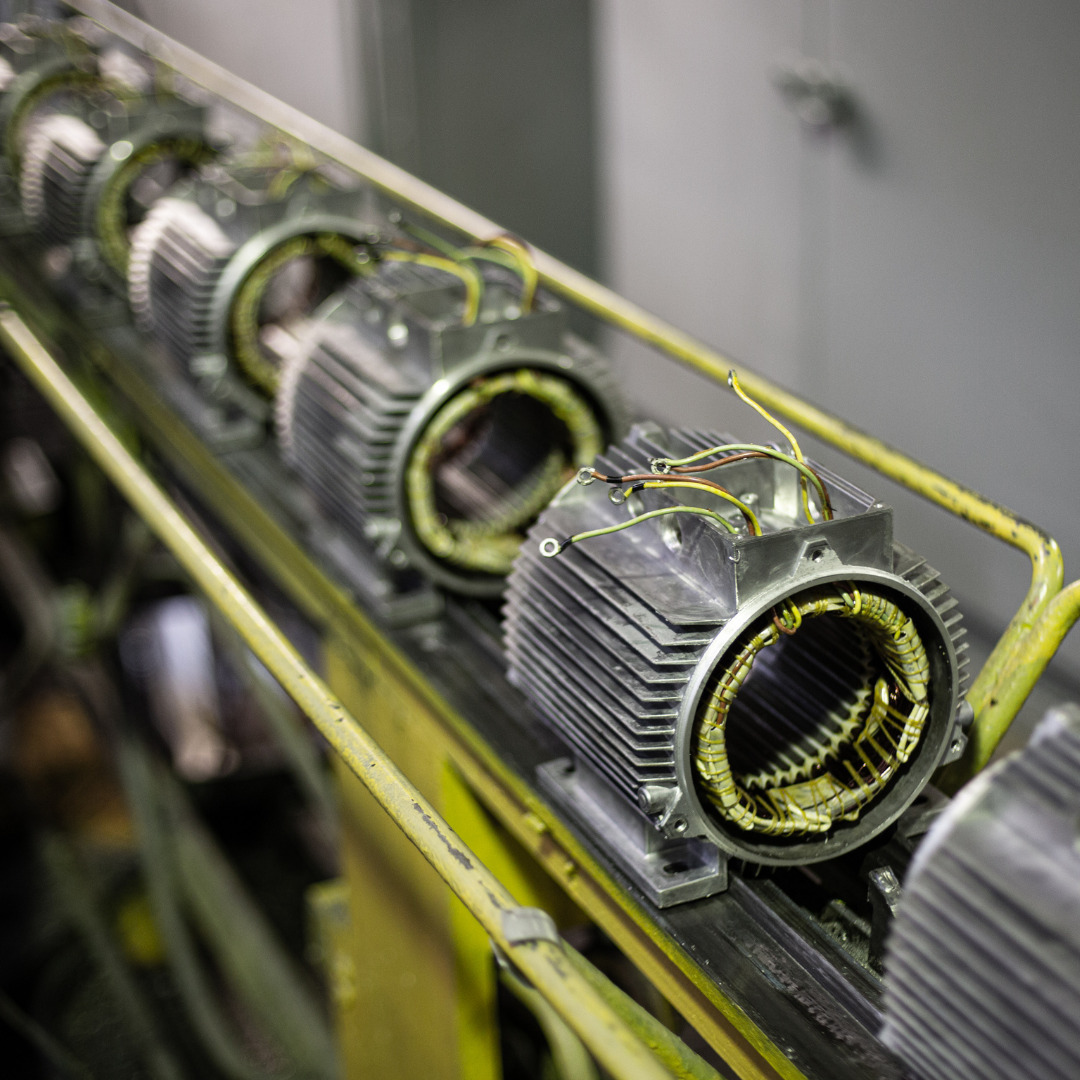

TAKE-BACK AND RECYCLING PROGRAMMES

EATON has established take-back and recycling programs for products such as batteries, circuit breakers, transformers and electromotors.

Customers can return their used products for free or at a discount. these products are then disassembled into their individual components, which are recycled to recover copper, steel and aluminium.

REUSE

Often for products in good condition (with minor repairs needed), EATON reuses parts from damaged products.

RENOVATION

EATON remanufactures electric motors and circuit breakers with the same warranties, significantly cheaper.

BEKO

BEKO has introduced a range of devices that contain parts made from recycled nets, industrial thread waste and recycled plastic bottles.

WASHING MACHINES

In the manufacture of tubs for washing machines and dryers recycled plastic bottles are used, accounting for up to 10% of the materials used in each tub.

OVENS

Using innovative technology, they recycle fishing nets and turn them into high-efficiency materials that are used in the door decor plastic, the display cover and the inner plastic display cover.

FRIDGE-FREEZER

Parts and accessories are made of biological sources, such as sugar cane, waste from eggshells and soybean oil.

These examples clearly show how the circular economy can work in practice. Companies committed to this model not only protect the environment, but also gain a positive reputation in the eyes of customers and increase their competitiveness on the market.

The circular economy is expected to be an even more important aspect for companies in the future. The trend towards sustainable production and consumption will gain importance, and companies that will have a leadership position in this area will be able to not only minimize their ecological footprint, but also thrive in a dynamic and shrinking world of resources.

WE HAVE SUMMARIZED THE IMPORTANT INFORMATION IN THE FLYER, WHICH YOU CAN VIEW AND DOWNLOAD HERE.